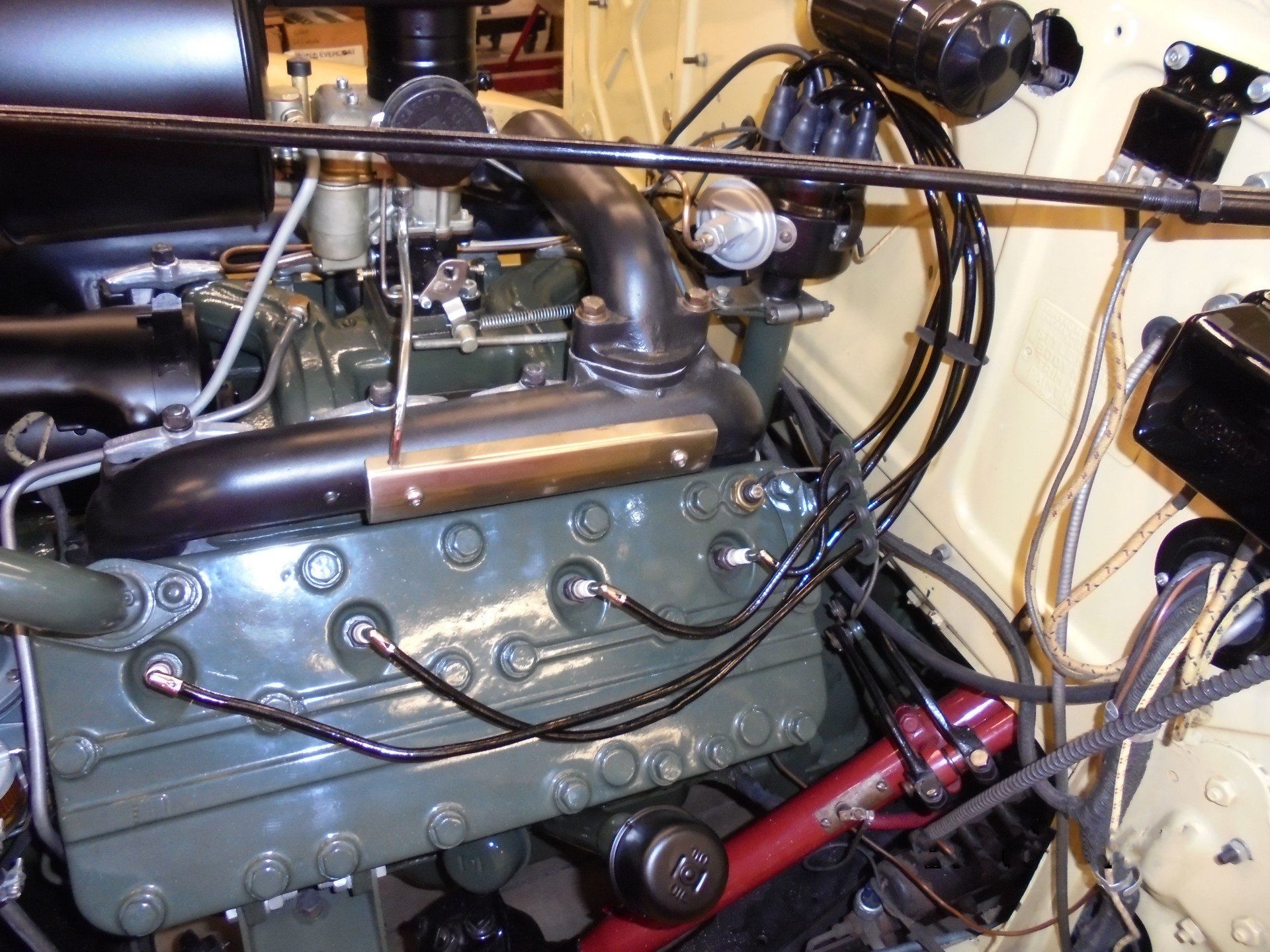

Engine Rebuilding

When an engine is worn beyond its mechanical limits, it gets rebuilt. The engine is completely disassembled. Every part--every nut, bolt and washer included--gets cleaned and prepared for final refurbishment. All engine components are inspected and measured to ensure that they are serviceable and to factory specifications. All items that do not pass inspection get replaced or repaired.

All parts showing wear get machined or replaced with new items which include valves, pistons, bearings, seals, o-rings, rubber or plastic parts, and gaskets. External coating on engine cases, cylinders, heads and valve covers are applied. Special attention is given to apply proper finishes to all engine components as were originally applied in the manufacturing process. We do extensive research and, in many cases, hours of labor to achieve results of making your engine appear as it did when it was originally manufactured.

The engine is reassembled and the final touches, such as original decals, data tags and markings, are applied.